Learn More About Nanocrystalline Cores

Magnetics manufactures a full range of nanocrystalline cores, including toroids, cut cores and busbar geometries, and supports tailored configurations beyond standard offerings. With rapid sampling, low minimum order quantities and engineering support available at every stage, you can explore both standard and custom solutions for performance-critical applications.

Nanocrystalline vs. Ferrite vs. Amorphous

While ferrite, amorphous and nanocrystalline cores all serve critical roles, each material type offers distinct advantages based on application requirements.

Material | Primary strengths | Best-fit applications |

High permeability, low loss, thermal stability, size reduction | EMI filters, CTs, UPS, EV power, SMPS | |

Low cost, good mid-frequency performance up to 3 MHz | General EMI suppression, low-cost designs | |

Moderate permeability and loss, thermal stability, high resistivity and saturation flux density, lower cost than nanocrystalline | 1 kHz – 20 kHz power conversion, high current, stable inductance |

Nanocrystalline Cores

Nanocrystalline provides high permeability (up to 80,000), low core loss and stable performance across a wide temperature and frequency range. These key characteristics enable engineers to design compact and efficient EMI filters, current transformers and inductive components. They also support higher current and lower DC resistance in smaller core sizes, deliver strong broadband attenuation and permit compact filter designs with low power loss and high rated currents. And in applications operating from 10kHz to 5 MHz (in rare cases as low as 1kHz or as high as 30 MHz), nanocrystalline offers potential size reductions with lower heat generation and higher impedance than ferrite or amorphous soft magnetic cores.

Compared to MnZn ferrite, nanocrystalline offers up to 12x higher permeability, 3x higher current handling and lower DC resistance, all while maintaining stable magnetic performance across a wider temperature range.

Ferrite Cores

Ferrites, especially MnZn compositions, can seem like a cost-efficient option for many EMI suppression and transformer applications — but they are not always a lower-cost option compared to nanocrystalline. The 80K permeability of nanocrystalline can allow for smaller core sizes. Ferrites perform well up to 2-5 MHz, though newer materials can extend performance to higher frequencies. They also maintain wide availability across standard geometries, making them well-suited for basic EMI filtering where minimization is less critical.

Amorphous Cores

Amorphous alloys offer a distinct mix of high flux density, moderate permeability and lower core loss than ferrite. While they are more lossy than nanocrystalline, their performance becomes compelling in low-frequency designs, especially below 10 kHz. Amorphous cut cores provide a firm inductance when a flat stable inductance is required at high currents in power applications. Engineers prefer amorphous cores in medium-frequency applications that require incremental improvements over ferrite, but the budget cannot justify the use of nanocrystalline cores.

Tailor Your Core to the Design

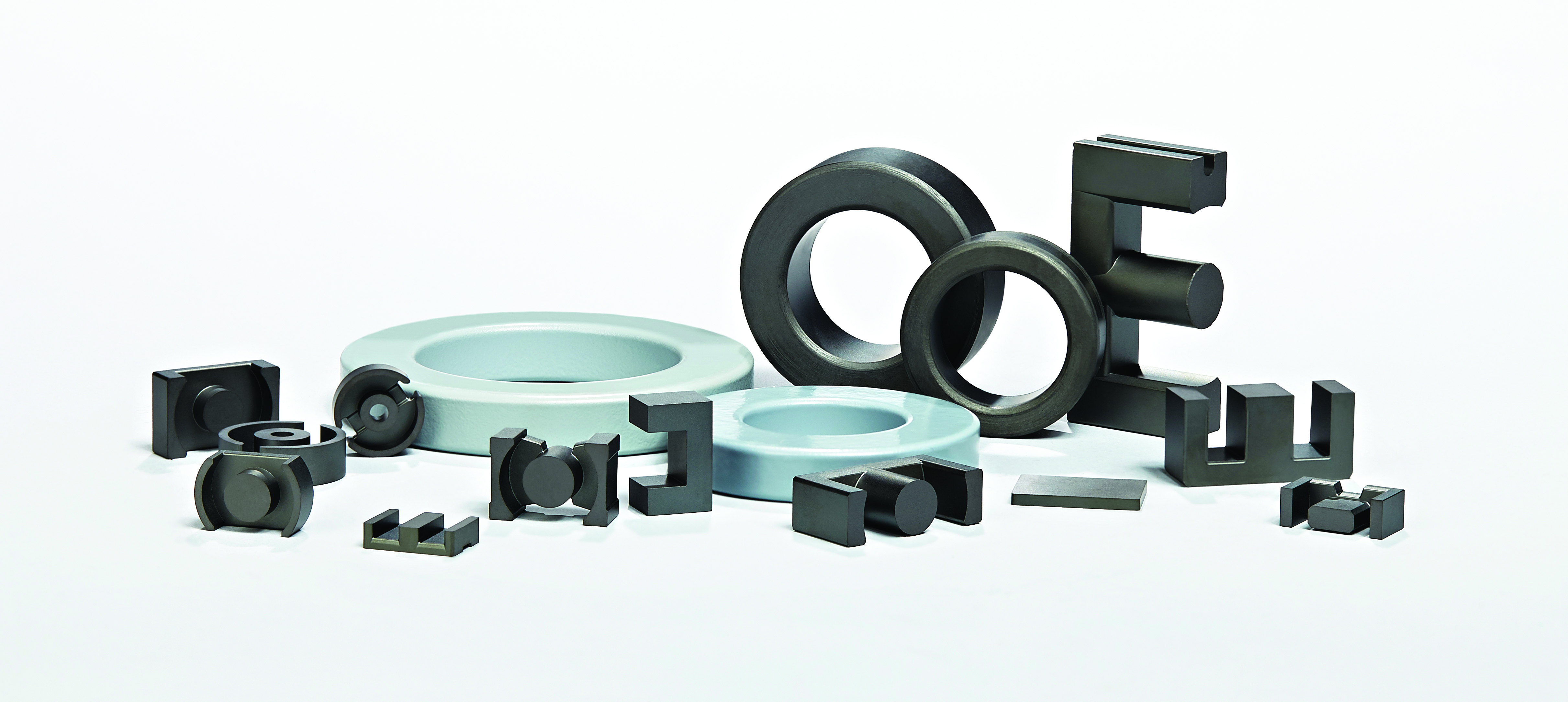

Nanocrystalline cores by Magnetics are engineered for performance-critical designs, with post-processing and configuration options that fine-tune magnetic and mechanical fit for your application.

Key design and customization factors include:

- Multiple anneal treatments: Optimize through permeability, core loss and saturation behavior for common-mode suppression, current sensing, power conversion or magnetic amplification.

- Thermal coating options: Standard and high-temperature coatings rated to 120°C and 155°C, respectively, for thermal stability and mechanical protection in demanding environments.

- Core geometries and modifications: Toroids, cut cores, U-cores and busbar-compatible shapes, with engineering support for modifications to outer diameter (OD), inner diameter (ID), height and custom slotting for specialized assemblies.

- Support for one-turn EMI filters and low-turn busbar cores: Beyond the catalog listings, specialized geometries for compact, high-current EMI suppression are available, with design assistance for winding and assembly integration.

Is Nanocrystalline Right for your Application?

Let’s Find Out Together!

Our engineering team can help evaluate your application requirements and recommend the best material for your frequency, thermal and size targets. For specialized configurations, we can also assist with application-specific recommendations and sample development, typically with a 2-4 week turnaround and low minimum order quantity requirements.

And if you already know your material and geometry requirements, you can explore Magnetics’ full range of nanocrystalline cores with our Part Finder tool.

Ready for a fast sample? Need to confirm material fit? Magnetics is here.