How To Order Magnetics Powder Cores

Magnetics powder cores have unique part numbers that provide important information about the characteristics of the cores. A description of part type is provided below.

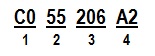

Toroids

1. Grading Code

- C0 = Graded into 2% inductance bands (OD <5 mm, 5% bands)

- 00 = Not graded

2. Material Code

- 55 = MPP

- 58 = High Flux

- 59 = Edge® / HIgh DC Bias Edge*

- 70 = Kool Mµ® Ultra

- 74 = XFlux® Ultra

- 75 = 75-Series

- 76 = Kool Mµ® Hƒ

- 77 = Kool Mμ®

- 78 = XFlux® / High DC Bias XFlux*

- 79 = Kool Mμ® MAX

3. Catalog Number

- Designates size and permeability

4. Core Finish Code

| Core Finish | Voltage Breakdown | Material Availability | OD Size Availability |

|---|---|---|---|

| A2 | 2,000 volts min** | MPP, High Flux, Edge | All |

| A7 | 2,000 volts min** | Kool Mµ, Kool Mμ MAX, Kool Mµ Hƒ, Kool Mµ Ultra, XFlux, XFlux Ultra, 75 Series | All |

| AY | 600 volts min | All (not available in 550µ MPP) | 3.56 - 16.6 mm |

| A9 | 8,000 volts min | All | >4.65 mm |

| W4 | 1,000 volts min | MPP | >4.65 mm |

| M4 | 1,000 volts min | MPP | >4.65 mm |

- *High DC Bias Edge and High DC Bias XFlux contain -S01 suffix

- **A2 and A7 voltage breakdown min varies by size:

- 1000 VAC with OD ≤4.65mm

- 1250 VAC with 4.65mm < OD < 17.27mm

- 2000 VAC with 17.27mm ≤ OD < 26.92mm

- 3000 VAC with OD ≥26.92mm

- UL rating is available upon request and contains -UL suffix

- Custom height toroids available based on pressed height or coated height

- Pressed height part suffix example: P185 suffix for pressing to nominal bare core height of 18.5 mm

- Coated height part suffix example: HT330 suffix for maxcoated height of 33.0 mm

Powder Core (Toroid) Stamping Summary

| Size (O.D. mm) | 6-digit Shop Order Number | 2-digit Material Code | 3-digit Catalog Number | 2-digit Core Finish Code | Inductance Code | Inductance Example |

|---|---|---|---|---|---|---|

| 6.35-6.86 | • | • | • | 123456 020 +6 | ||

| 7.87-12.7 | • | • | • | • | 123456 050A2 +6 | |

| >12.7 | • | • | • | • | • | 123456 55120A2 +6 |

- Inductance Code is only stamped on MPP and High Flux toroids with C0- Grading Code.

- Shop Order number identifies the product batch, ensuring traceability of every core through the entire manufacturing process, back to raw materials.

- Cores with O.D. less than 6.35 mm are not stamped.

Powder Core Toroid Stamping Examples

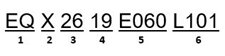

EQ/LP/EER Shape

1. Shape Code

- EQ = EQ geometry

- LP = LP geometry

- ER = EER geometry

2. Material Code

- G = Edge®

- H = High Flux

- K = Kool Mµ®

- X = XFlux®

- Y = Kool Mµ® MAX

3. Size Code - Back Wall

- Back wall length in mm

4. Size Code - Width

- Width in mm

5. Permeability Code

- E026 for 26µ

- E040 for 40µ

- E060 for 60µ

- E075 for 75µ

6. Size Code - Leg

- Leg length in mm (i.e. 101 for 10.1 mm)

Other Non-Toroidal Shapes and THINZ

1. Grading Code

- 00 = Not graded

2. Material Code

- F = Kool Mµ® Hf

- G = Edge®

- H = High Flux

- K = Kool Mµ®

- M = MPP

- X = XFlux®

- Y or A= Kool Mµ® MAX

3. Size Code

- First two digits = length in mm

- Last two digits = height in mm *not listed for Large E Cores

3. Shape Code

- E = E Core

- LE = Large E Core

- T = Toroid (THINZ)

- U = U core

- P = I Core/Plate

- B = Blocks

- LB = Large Block ("A" dimension longer than 99 mm)

- R = Round Block

4. Permeability Code

- 014 for 14µ

- 026 for 26µ

- 040 for 40µ

- 060 for 60µ

- 075 for 75µ

- 090 for 90µ

Non-Toroidal Shapes Stamping Example EQ Shape Stamping Example

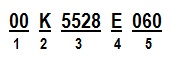

Cylinders

1. Grading Code

- 00 = Not graded

2. Material Code

- G = Edge®

- H = High Flux

- K = Kool Mµ®

- X = XFlux®

3. Size Code: OD in integer mm

4. Size Code: HT in integer mm

5. Shape Code

- C = Cylinder

6. Permeability Code

- 014 for 14µ

- 026 for 26µ

- 040 for 40µ

- 060 for 60µ

- 075 for 75µ

- 090 for 90µ